Hot steel descaling is one of the most unforgiving duties in a rolling mill. The job sounds simple—remove oxide scale using high-pressure water jets before the material enters the deformation zone. But in practice, descaling performance depends on whether your system can deliver repeatable jet impact energy at line speed, heat after heat, shift after shift.

That requirement collapses into a handful of engineering truths:

- Descaling needs stable pressure at the nozzle, not only at the pump outlet.

- Descaling needs flow rate matched to billet/bloom/slab size to evacuate fractured scale.

- Descaling needs jet coherence (water quality + filtration + nozzle condition) to maintain impingement force.

- Descaling needs reliability under harsh plant conditions: scale-laden water risk, cyclic valve operation, transients, and thermal shocks.

This is exactly why the reciprocating plunger pump for descaling remains the preferred choice in modern hydraulic descaling—especially in the common steel plant ranges of 150, 200, 300, and 400 bar, depending on grade and scale adhesion.

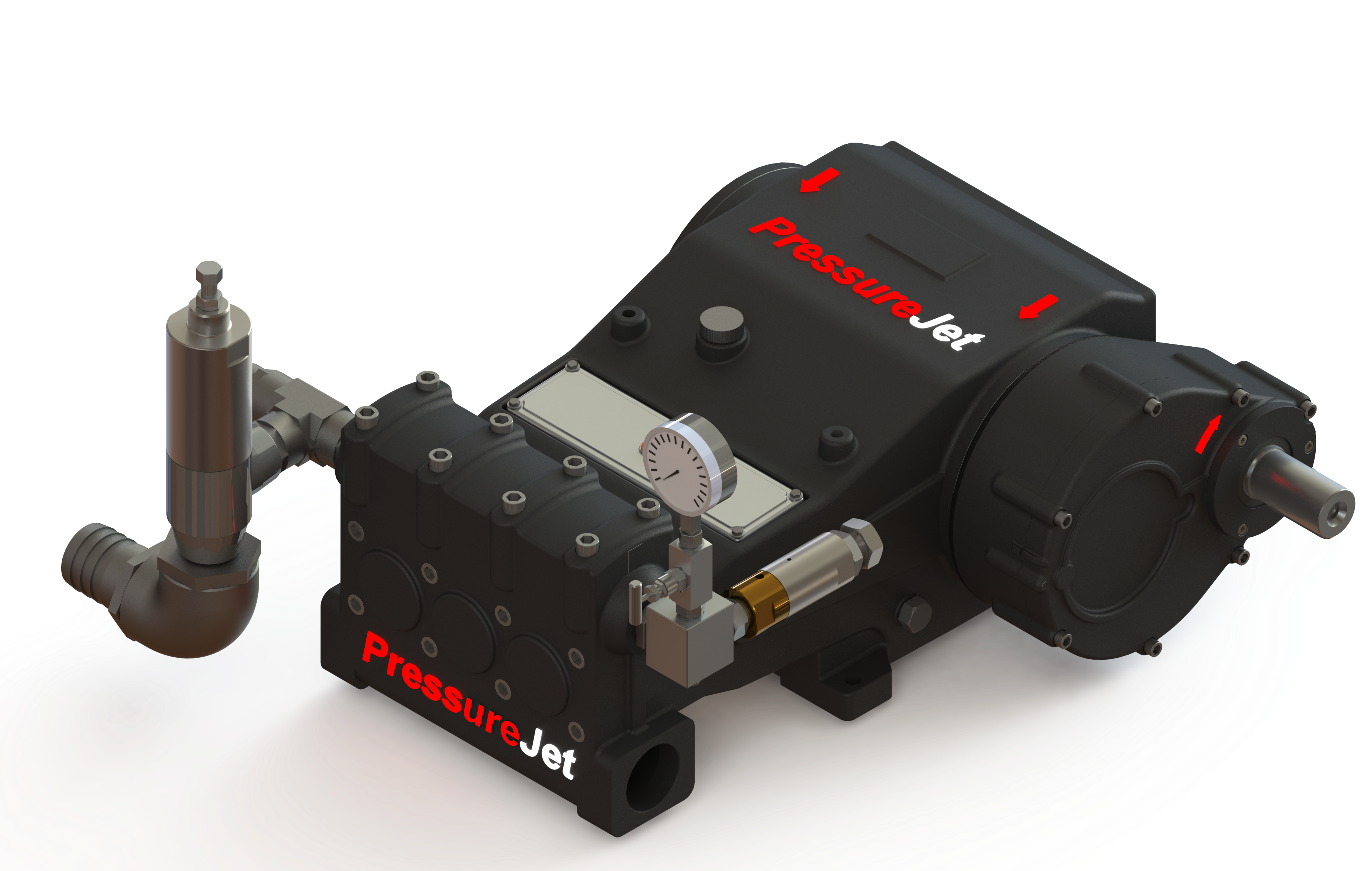

This blog is written on behalf of PressureJet, known in the industry for high-pressure reciprocating pump systems and application-focused descaling engineering.

1) Descaling Is a “Hydraulic Power Delivery” Problem (Not Just a Water Supply Problem)

A rolling mill descaling header is not a sprinkler. It is a device for delivering hydraulic power—converted into water-jet kinetic energy—onto a hot steel surface.

The scale layer (FeO/Fe₃O₄/Fe₂O₃) forms aggressively during reheating. If it is not removed, it becomes “mill garbage” downstream: it embeds into rolls, triggers third-body abrasion, and drives defects and roll wear. The water jet must exceed the adhesion strength of the scale-to-metal interface through combined thermal shock and mechanical impact.

Jet effectiveness depends on the energy delivered at the target, which is governed by:

- Nozzle pressure (bar)

- Total flow (LPM) & distribution across the width

- Nozzle geometry and stand-off distance

- Valve response and timing

- Stability (minimal fluctuation)

This is where pump type matters. Some pumps move water well, but cannot reliably hold high pressure under dynamic conditions. Descaling demands the opposite: pressure stability first, flow stability second, both delivered consistently.

2) Why a Reciprocating Plunger Pump Fits Descaling Better Than Dynamic Pumps

A reciprocating plunger pump for descaling is a positive displacement pump. It moves a defined volume of water each stroke. Pressure is not “created” by impeller velocity like a centrifugal pump; pressure is generated when that fixed displaced volume is forced through restrictions (nozzles, piping, valves).

What that gives you in a rolling mill:

- Stable high pressure across a wide operating window

- Better control of pressure and flow under changing header demand

- High suitability for typical descaling pressures (200–300 bar) and higher-duty requirements (up to ~400 bar) when justified

Centrifugal pumps dominate low-pressure/high-flow applications. But hydraulic descaling is high pressure by nature. As head requirements rise, centrifugal designs require multiple stages, very tight internal clearances, and pristine water quality to remain efficient and reliable. In the steel plant reality—where water quality and transients exist—positive displacement technology is simply a more robust fit for the descaling duty.

3) Pressure Range Reality: 150 vs 200 vs 300 vs 400 Bar—Why Plunger Pumps Scale Well

Rolling mills don’t use a single universal descaling pressure. Typical patterns:

- 150 bar: light-duty scale removal, limited conditions

- 200 bar: common for many mild steel scenarios

- 300 bar: widely used for demanding conditions and alloy steels (stronger scale adhesion)

- 400 bar: special cases (very adherent scale, specific mill layouts, high-grade steels)

As pressure increases, the system becomes more sensitive to pressure loss across piping, valves, filters, and nozzles. The advantage of a hydraulic descaling pump based on plunger design is that it is inherently comfortable operating at these pressures, provided the system is engineered correctly (pulsation control, filtration, valve selection, piping design).

Important: Pressure alone is not a guarantee. A 300 bar pump feeding worn nozzles can deliver worse descaling than a 200 bar system with correct nozzle condition and correct flow distribution.

4) Volumetric Efficiency: The Quiet KPI That Predicts Descaling Performance

In real mills, engineers often track “pressure” and ignore efficiency indicators until problems explode. For plunger pumps, one of the best early indicators is volumetric efficiency—the ratio of actual delivered flow to theoretical displacement.

When volumetric efficiency drops, the pump may still show pressure on the gauge, but the system’s ability to sustain flow at pressure degrades. That translates into:

- weaker impingement force at the nozzle

- incomplete scale evacuation

- more debris entering stands

- roll wear and surface defects increasing over time

A well-maintained reciprocating plunger pump for descaling maintains strong volumetric efficiency because internal slip is controllable via sealing condition and valve health. This makes performance monitoring practical: trend pressure + flow together, not pressure alone.

5) Why Pressure Stability Matters More Than Peak Pressure

Descaling failures rarely happen because a system can’t reach peak pressure for a moment. They happen because pressure fluctuates and the jet loses coherence at the wrong time.

A stable jet delivers stable impact energy. When pressure pulses are excessive or supply is unstable, you get:

- uneven scale fracture

- partial removal with re-adhesion

- “striping” patterns and inconsistent surface finish

- higher risk of scale entering roll gaps

Plunger pump systems, when paired with pulsation dampeners/accumulators and correct piping design, are highly capable of delivering the stable pressure profile descaling needs—especially when valves cycle on and off with billet tracking.

6) Valve Cycling and Transients: A Real Descaling System Is Not Constant Flow

Many descaling systems operate with fast on/off valves and zone control:

- billet tracking triggers the header

- valve opens for the billet, closes after it passes

- sometimes multiple headers or zones activate sequentially

This creates transients and sudden demand changes. In these conditions, a positive displacement pump behaves like a controlled hydraulic power source rather than a flow device that “hopes” pressure follows.

With proper system engineering (dampeners, relief protection, and valve sizing), plunger pumps handle cyclic duty better and allow consistent nozzle pressure—critical for rolling mill descaling.

7) Flow Rate Must Be Section-Specific: Why Plunger Pumps Support That Control

Descaling is not just pressure—it is pressure + coverage + evacuation.

Flow rate must be tailored to:

- billet size (e.g., 100/120/150/160 mm square)

- bloom/slab width and thickness

- surface area exposure

- header layout and nozzle arrangement

If flow is too low at a given pressure, scale may crack but not evacuate; it re-enters the roll gap as abrasive debris. If flow is too high, you risk excessive billet cooling and energy penalties.

A reciprocating plunger pump for descaling supports controlled flow delivery at high pressure. In practice, flow is managed by system design: nozzle selection, header zoning, and valve control—while the pump provides stable high-pressure supply.

8) Water Quality & Filtration: Plunger Pumps Are Strong, But Nozzles Are Sensitive

To be blunt: descaling nozzles are precision orifices operating in a dirty world. Filtration discipline is non-negotiable. Poor filtration causes:

- nozzle blockage → jet distortion → incomplete descaling

- nozzle erosion → increased orifice → pressure loss at impact

- valve seat wear → leaks and response issues

- pump valve wear → efficiency loss

A hydraulic descaling pump can only perform if the system protects the downstream components. Good descaling systems use staged filtration and monitor differential pressure (ΔP) so clogging is detected early—before nozzle pressure drops and rolling problems begin.

Plunger pump systems are often favored because, even in real plant conditions, their maintenance points are clear and controllable—when filtration and monitoring are properly implemented.

9) Suction Stability, NPSH, and Booster Pumps: Where Many Mills Lose Performance

In high-pressure systems, discharge looks dramatic, but suction is where many failures start.

If suction conditions are poor:

- cavitation occurs

- pressure fluctuates

- pump valves chatter

- seals suffer

- volumetric efficiency drops

This is why descaling skids often use a booster pump and robust suction filtration to ensure stable inlet conditions. Monitoring booster pump filters is a practical troubleshooting step when pressure drop or instability appears at the header.

A reciprocating plunger pump for descaling performs best when the inlet is stable and well-fed. Treat suction engineering as seriously as discharge engineering.

10) Maintenance Predictability: Why Mills Prefer Plunger Technology

Rolling mills don’t just want performance—they want predictable service intervals.

Plunger pump maintenance is mechanical and trackable:

- packing/seals

- pump valves (seat/disc condition)

- plunger surface condition

- crankcase lubrication health

- vibration/temperature trends

And the most useful “operational KPI” is again volumetric efficiency trend—pressure + flow vs time.

In contrast, multi-stage centrifugal systems operating at extreme heads can become sensitive to wear and clearances in ways that are harder to diagnose early, especially in imperfect water conditions.

11) Common “Pump Problems” That Are Actually System Problems (Troubleshooting Logic)

When mills complain “descaling is weak,” the cause is often not the pump. A field-practical troubleshooting sequence:

- Check nozzle tips

- Look for erosion (orifice growth) and blockage

- A worn nozzle can drop effective impingement force even when pump pressure reads “okay”

- Verify pressure at the header/nozzle, not only at the pump outlet

- Line losses, valve issues, and filter choking hide between pump and nozzle

- Inspect valve condition and guides

- On/off valve wear or guide issues can cause restriction or delayed jet timing

- Timing errors mimic “low pressure” at the workpiece

- Monitor booster pump filters and suction stability

- Choked filters reduce infeed → cavitation and pressure instability

- This can appear as random pressure drops during operation

- Trend volumetric efficiency

- If flow falls at the same pressure, internal wear may be growing

- Address before the system becomes unstable at peak demand

This systematic approach prevents unnecessary downtime and avoids replacing healthy components.

Conclusion: The Engineering Reason Plunger Pumps Win in Descaling

A rolling mill descaling system is only as good as its ability to deliver repeatable, stable jet impact energy. The reciprocating plunger pump for descaling remains ideal because it naturally fits the core requirements:

- Reliable high-pressure operation across 150–400 bar system ranges (as required)

- Strong and controllable volumetric efficiency

- Better pressure stability under valve cycling and transient duty

- Predictable maintenance and diagnosable wear patterns

- Compatibility with engineered filtration, booster infeed, and robust nozzle systems

PressureJet’s reputation in descaling applications comes from treating the pump not as a standalone item, but as the heart of a complete high pressure descaling system—pressure stability, flow matching, filtration discipline, and maintainability engineered together.

When these fundamentals are correct, mills see what matters: cleaner steel entering stands, longer roll life, fewer scale-driven defects, and a more stable rolling process.

Contact our experts today for a customized descaling solution.

- Visit: www.pressurejet.com

- Specialized Portal: www.steeldescaling.com